Surge reason

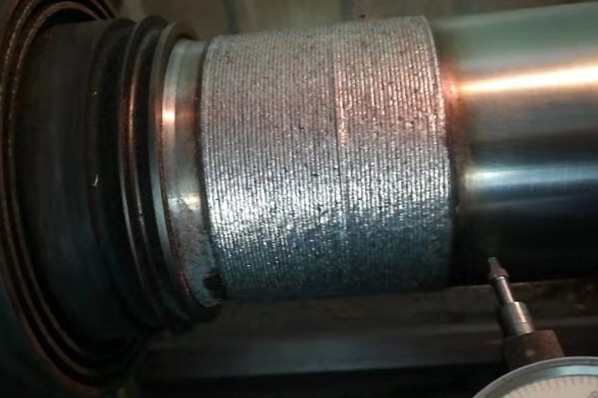

Generally, when selecting the supercharger, the suitable position on the right side of surge line B is selected for the compressor matching line according to the working characteristics of different supercharging systems. At this time, it can not only ensure that the diesel engine reaches the predetermined supercharging index and the supercharger works in the high efficiency area, but also ensure that the supercharger does not surge within the whole working range of the diesel engine. Therefore, under normal circumstances, there is no surge. However, when the working conditions change, such as when the supercharging system channel is blocked, the load is too high or too low, the diesel engine load is uneven, and the load is sudden and so on, the working line will partially or completely enter the surge zone, causing surge. Here are some possible causes of supercharger surge. One of the direct consequences of channel obstruction in supercharger system is to increase the resistance of airflow in the system. During the operation of diesel engine, the gas flow route of the supercharging system is as follows: compressor inlet filter and silencer → compressor impeller → compressor diffuser → air cooler → scavenger → diesel engine inlet (valve) → exhaust port (valve) → exhaust pipe → exhaust turbine nozzle ring → exhaust turbine impeller → chimney. The circulation area of each component is fixed. If any link of the above flow path is blocked, such as dirt, carbon, deformation, etc., it will increase the back pressure of the compressor due to the increase of flow resistance, reduce the flow, causing surge. Among the easily dirty parts are compressor inlet filter, compressor impeller and diffuser, air cooler, diesel engine inlet (sweep) air port and exhaust port (valve), exhaust gas turbine nozzle ring, exhaust gas turbine impeller. Under normal circumstances, the main reason for the surge is the blocking of the flow channel of the turbocharger. The above parts shall be regularly inspected for defilement and cleaned in the management so that the surge caused thereby can be prevented or eliminated.

Blocking factors

Diesel engine operating conditions (load, speed) change diesel engine running at low speed and high load, when the diesel engine failure or ship full load, wind, pollution bottom increase the external load, diesel engine speed decline, at this point the governor automatically increase the oil supply, so that the diesel engine in low speed, high load operation. Due to the increase of oil supply and exhaust gas energy, it will inevitably lead to the increase of supercharger speed and the increase of compressor exhaust and discharge pressure. But at this time, the diesel engine speed is low, less gas consumption, so that the supercharger gas supply and diesel engine gas consumption between supply and demand balance is broken. As the back pressure of the compressor increases, the flow decreases, which results in that when entering the low-temperature sea area, the air density increases due to the lower ambient temperature, so the intake of the compressor increases, which increases the energy obtained by the turbine. As the speed of the supercharger increases, the operating line moves to the lower part, and the surge margin increases. On the contrary, when entering the high temperature sea area, the surge margin is reduced, which is prone to surge. But for some ships in the low temperature navigation area match the pressurized diesel engine with no air cooler sailing in the high temperature sea area, or in the high temperature navigation area match the pressurized diesel engine with air cooler sailing in the low temperature sea area, because of the change of the matching relationship between the two, the running point is easy to close to the surge area, causing surge.

Fault injection

When the fuel injection system failure, the use of low-quality heavy oil, after the aggravation of combustion, exhaust temperature is high. No matter full load or partial load, no matter how serious the afterburn is, its coordinated operation point is on the normal coordinated operation line. With the delay of the combustion end point, the exhaust temperature increases, the supercharger speed increases, the compressor flow increases, the pressure ratio increases, and the running point moves to the higher part of the curve with less surge margin.

Cooling variation

When the cooling capacity of the air cooler decreases, the exhaust temperature of the diesel engine increases, the compressor speed increases, and the surge margin decreases as the running point moves higher.

In short, non-channel blocking factors will not affect the flow characteristics, will not change the supercharger and diesel engine with the operating line position, only change the supercharger and diesel engine with the operating point position in the line, is the secondary cause of the turbocharger surge.